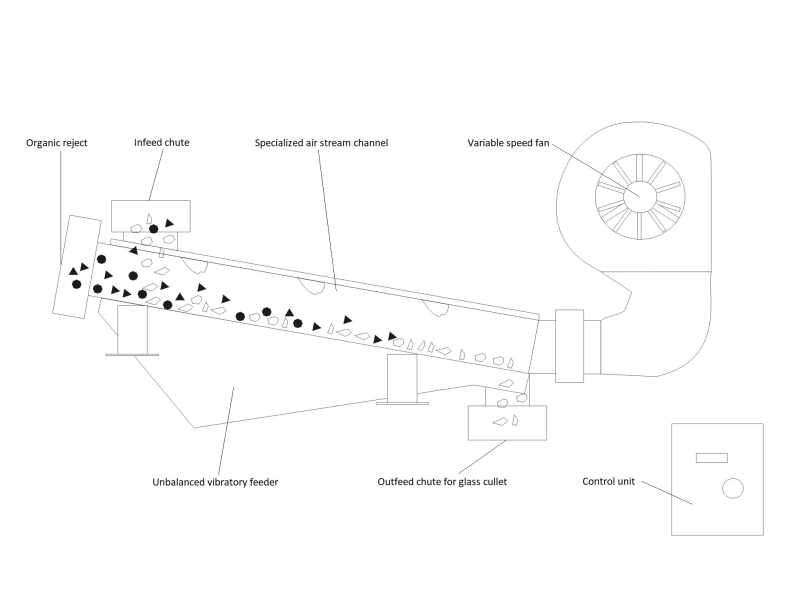

- For separation of organic and plastic materials

- Applicable for container, flat and MRF glass recycling

- Suitable for dry and wet input material

ORGANIC AND PLASTIC SEPARATION

AVAILABLE VERSIONS

| ORSE Type | Working width | Max.

throughput capacity* | Application |

| A | 450 mm | 6 t/h | Cullet (5-60 mm) |

| B | 600 mm | 10 t/h | Cullet (5-60 mm) |

| C | 625 mm | 10 t/h | Pre-sorting of MRF glass, unbroken container glass or pre-shredded flat glass |

| D | 2 x 610 mm | 20 t/h | Pre-sorting of MRF glass, unbroken container glass or pre-shredded flat glass |

* Depending on the amount of impurities, cullet size and moisture of the input material.

FEATURES

- Separation of all light impurities

The counterflow air channel reliable blows out impurities with a lower specific weight than glass. - Organic Pre-Sorting of MRF-, unbroken container- and pre-shredded flat glass

The organic content of MRF-, unbroken container resp. collected glass and pre-shredded flat glass can be reduced to a minimum by ORSE-C and ORSE-D separators. - Separation performance

The variable adjustment of the air speed allows a precise differentiation between broken glass and lighter impurities. - Horizontal air flow

Due to the horizontal arrangement, impurities do not have to be lifted vertically. This results in a much better degree of separation compared to conventional suction nozzles or zigzag classifiers. - Multiple separation

Parts that are difficult to blow out and which are not completely separated on the first air flow get several chances to be caught by the increased air flow at the end of the conveyor trough. This increases the separation reliability even for difficult impurities. - Info

Depending on the application, the dust content and specific regulations, additional dust filtering might be required.