- Metal separation out of glass cullet

- Applicable for container and flat glass recycling

- Suitable for dry and wet input material

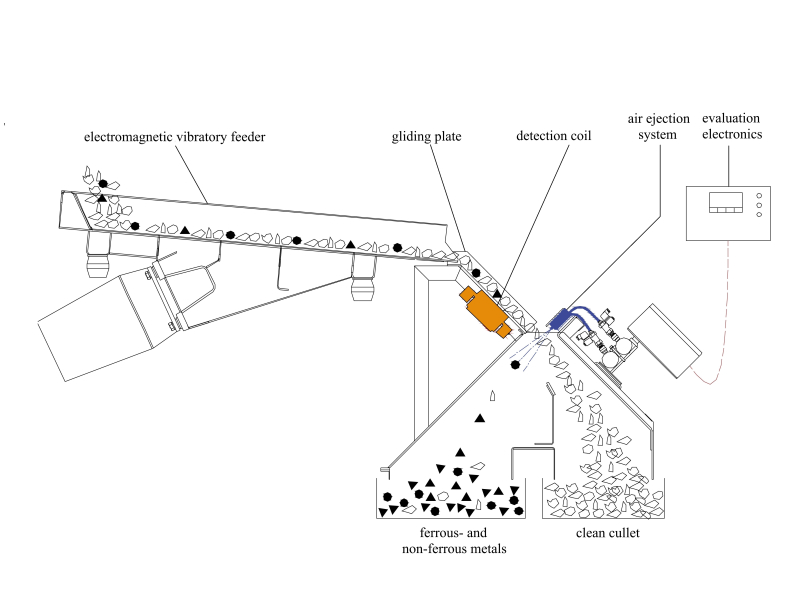

FERROUS (FE) AND NON-FERROUS (NE) METAL SEPARATION

AVAILABLE WORKING WIDTHS AND VALVE GRIDS

| Working width | Max.

throughput capacity* | Number of valves [Valve distance] |

| 1024 mm | 12 t/h | 64 [16 mm] |

| 1280 mm | 16 t/h | 80 [16 mm] |

| 1536 mm | 18 t/h | 96 [16 mm] |

| 1920 mm | 22 t/h | 120 [16 mm] |

* Depending on the amount of impurities and cullet size.

FEATURES

- Detection of all kind of metals

All Ferrous (FE) and non-Ferrous (NE) metals can be reliably detected by the high frequency detection coil. - Multi-channel coil system

Due to the multi-channel detection coil which is divided into several individual sectors a position-accurate detection is possible. - High detection accuracy even with fine glass

- Precise separation

High-speed magnetic valves with a long working life ensure a precise separation of metal impurities. - Lowest glass loss

The detection by the high frequency coil ensures reliable separation with minimal glass loss. - Suitable for dry and wet input material

Due to the freefall system the MAG separator works even well for wet cullet.